Hydraulic cold press machines are revolutionizing modern woodworking by providing unparalleled bonding quality, material versatility, and efficient, reliable operation. Companies like Kataria Tech Zone in Punjab offer advanced hydraulic cold press solutions tailored for the needs of professional woodworkers and manufacturers.

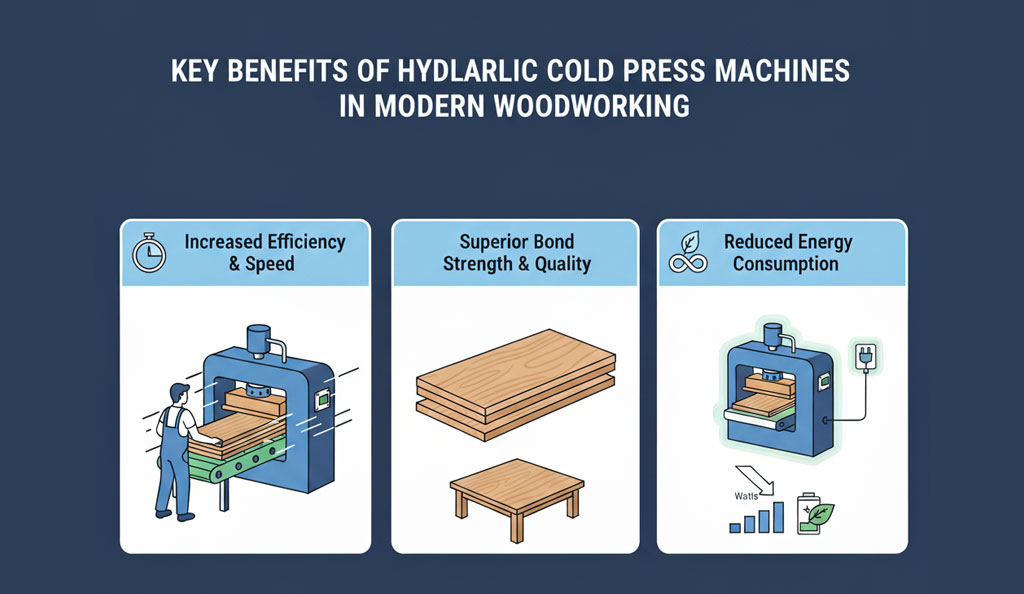

Key Benefits in Modern Woodworking

- Superior Bond Strength: Hydraulic cold presses deliver consistently strong and uniform pressure, resulting in durable bonds between layers of wood, veneers, laminates, and composite materials. This reliability helps prevent delamination and ensures superior structural integrity in furniture, cabinetry, doors, and decorative panels.

- Preservation of Natural Finish: Since cold pressing does not use heat, it preserves the natural color, texture, and properties of wood. This makes it ideal for high-end furniture and design work where authenticity and aesthetics are crucial.

- Material Versatility: Hydraulic cold presses handle a wide range of substrates, including plywood, MDF, particle board, solid wood, HPL, plastic laminates, and composite overlays. This flexibility expands the scope of projects and product offerings for woodworking businesses.

- Cost-Effective and Energy Efficient: Cold press machines typically consume less energy, as there are no heating elements involved. They are compatible with economical adhesives that cure at room temperature, reducing operational expenses and supporting sustainable production.

- Flawless Finish Quality: Cold press machines apply uniform pressure, producing perfectly flat, smooth surfaces without bubbles, wrinkles, or distortions—critical for subsequent finishing operations like sanding, painting, or polishing.

- Increased Productivity: Operators can load multiple panels simultaneously, maximizing output while minimizing downtime. The simple operation and high reliability help woodworkers meet tight deadlines without sacrificing quality.

- Improved Dimensional Stability: Laminating and veneering with hydraulic cold presses balances wood stresses, resulting in panels that are less prone to warping, cupping, or twisting over time.

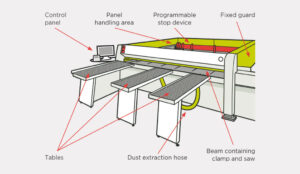

- Enhanced Safety: Modern hydraulic cold presses are equipped with overload protection, easy-to-adjust pressure controls, and multiple built-in safety features, reducing risk for operators and improving overall workplace safety.

By investing in hydraulic cold press technology from trusted suppliers like Kataria Tech Zone Punjab, woodworking businesses gain the ability to deliver consistent, high-quality products, reduce waste and rework, and operate efficiently in competitive markets.